Gurvich LV, Veyts IV, Alcock CB (eds) (1989) Thermodynamic properties of individual substances, 4th edn. Pedley JB, Naylor RD, Kirby SP (1986) Thermochemical data of organic compounds, 2nd edn. Government Printing Office, Washington, DC Parts I and II, American Institute of Physics, U.S. Stull DR, Prophet H (1986) JANAF Thermochemical Tables, 3rd edn.

Kubaschewski O, Alcock CB (1979) Metallurgical thermochemistry, 5th edn.

Mills KC (1974) Thermodynamic data for inorganic sulphides, selenides and tellurides. Hassell CA, Stasko DJ (2007) Chemistry: principles, patterns and applications. Noyes, Park Ridge, NJ, pp1–33Ītkins P, Paula J de (2006) Atkins’ physical chemistry, 8th edn. In: O’Mara WC, Herring RB, Hunt LP (eds) Handbook of semiconductor silicon technology. Hunt LP (1990) Silicon precursors: their manufacture and properties. Electrochemical Society, Pennington, NJ, pp112–121 In: Cullen GW (ed) Proceedings of the 10th international conference on chemical vapour deposition, Honolulu, HI. Hunt LP (1987) Thermodynamic equilibria in the Si-H-Cl and Si-H-Br systems. This process is experimental and the keywords may be updated as the learning algorithm improves. These keywords were added by machine and not by the authors. This chapter covers these topics and gives details on these processes. The overall deposition rate of the CVD process is limited by the slowest step in the three aforementioned steps. Among them, three important steps are: (1) homogeneous reactions taking place among the gases in a reaction chamber, (2) heterogeneous reactions occurring on the surface of a substrate and (3) mass transportation of the gaseous precursors. The kinetics of a CVD system involves many steps which determine the rate of the deposition process.

#CHEMICAL REACTION THERMODYNAMICS CALCULATOR FREE#

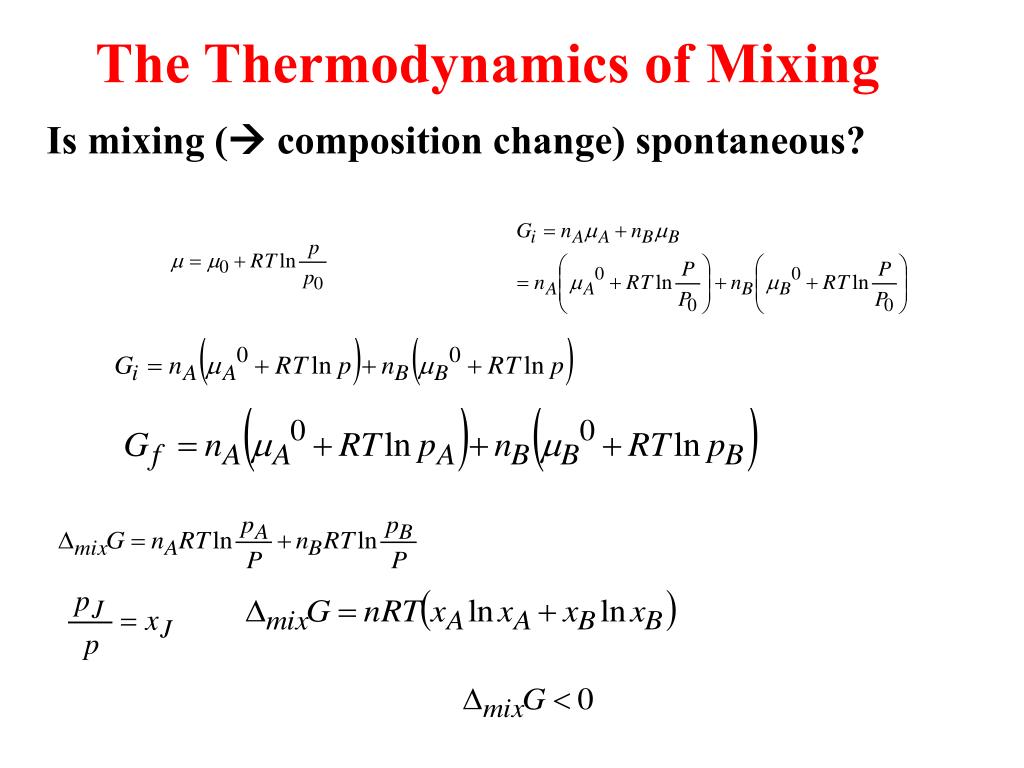

CVD phase diagrams are derived based on the minimisation of Gibbs free energy and are useful in predicting the equilibrium phases present in the chemical reaction system under given processing conditions determined by the deposition temperature, pressure and reactant concentration.Ī CVD process is also a non-equilibrium process and typically consists of complex chemical reactions. To ensure a high quality of a CVD coating it is essential to determine the feasibility of a particular CVD reaction first, then select the suitable precursors for the CVD processes. Thermodynamic studies of a CVD process are undertaken to provide a basic understanding of chemical reactions under equilibrium conditions.

0 kommentar(er)

0 kommentar(er)